MICROPOWER TC WASTE TRANSFORMATION SYSTEM

MICROPOWER CORPORATION focuses on development and implementation of advanced environmental technology to combat the catastrophic effects that poor water, forestry and waste management practices and fossil fuel dependencies have made on our health and economy. After years of exhaustive research, development and refinement cycles, the company is offering a community-friendly technology platform that transforms municipal, industrial, forestry and agricultural waste into gas, liquid and solid-based renewable energy components using a process that contributes to the restoration of our land, sea and air.

The MICROPOWER TC Waste Transformation System is organized along three fundamental principles:

1. Accept that the generation of waste is a reality, but treat it as a valuable resource that can be repurposed rather than as a liability that has no use.

2. Employ a decentralized and distributed approach to overcome the challenges presented by our current waste disposal policies and energy production methods.

3. When practical, use waste to create products that mitigate the damages caused by non-renewable energy generation and environmentally-unfriendly industrial processes that will continue to be utilized in the near future.

The Problem and the Opportunity it Creates

The Solid Waste Association of America (SWANA) estimates that each year over 1.5 billion tons of municipal, industrial, forestry and agricultural waste are produced in the United States with most of it condemned to our 1,812 active regional landfills where some 100 billion tons are already stored and emitting 16-percent of all man-made greenhouse gases (GHGs). While most of the population consumes without worrying about where their waste will ultimately be disposed, we are actually at the brink of an impending crisis. According to the US Environmental Protection Agency, 50-percent of all US regional landfills are already closed and 75-percent of those currently operating are slated for closure within the next 10 years. The expansion of regional landfills as well as the constructing of new facilities averages $1 million per ace; a significant burden for most municipal governments as they suffer the effects of a depressed tax base and a constituency opposed to any increase in spending. As regional disposal space quickly diminishes and waste must be hauled long distances to mega-landfills, tipping fees, currently averaging about $42 per ton, are rising uncontrollably at a rate of 3-percent annually. Worse yet, the indirect costs of disposal frequently run more than the tipping fees themselves. Waste Age Magazine estimates that expenses incurred during the transport of waste such as insurance, maintenance, fuel, wages, fines and tolls, can add $10 to $70 per ton in costs. Merely ceasing landfill operations brings about liabilities, as Section 6002, Part D of the Resource Conservation and Recovery Act requires costly maintenance, monitoring and public safety assurances for a period of no less than 30 years after closure, forcing owners to allocate millions of dollars to escrow accounts, insurance policies and recovery bonds. More often than not, the expense for these warranties, guarantees and lifetime liabilities are borne by taxpayers.

As our population continues to grow and society produces more waste, it is becoming increasingly difficult if not impossible to build new landfills because of the health and human safety issues that surround them. Typical landfill leachate and runoff contains nitrates, ammonia, solvents, PCBs and heavy metals causing pronounced groundwater contamination. Fuel-inefficient trucks transport thousands of tons of garbage hundreds of miles from the nation’s 8,905 transfer stations to communities that did not even generate the waste in the first place, prematurely wearing roadways and belching toxic exhaust. Worse yet, disposal sites are typically located in poorer areas of the country where increased rates of illness, birth defects, disease and absence from work seem to always be attributed to other factors despite evidence that millions of tons of garbage are most likely to blame.

At the same time, the long-term future of our non-renewable energy resources is frequently debated. According to the United States Energy Association, a remarkable 86-percent of total electricity consumption in the United Sates is generated by sources entirely dependent upon fossil fuels. Aside from concerns about the depletion of reserves, global oil supplies are threatened by accidents, war, terrorism and political instability. Commonly hailed as an Earth-friendly fossil fuel, natural gas has most of these same issues with only 6-percent of worldwide reserves, estimated to be only 60 years, located in the United States. On the other hand, the 722 coal-fired power plants which produce 55-percent of our electricity are also our largest source of mercury emissions and are directly responsible for a staggering 36-percent of all man-made GHG production, according to the US Environmental Production Agency. These plants not only pollute our air with toxic levels of sulfur and nitrogen oxides, bus also creates dangerous fly ash, 65-percent of which is disposed in landfills or held in 40-plus acre onsite retention ponds. Oakridge National Laboratory proved in 1988 that fly ash can be more radioactive than nuclear waste and contains arsenic, cadmium and other heavy metals, yet remarkably it is still not classified a hazardous material. A study by the National Renewable Energy Laboratory reveals that merely retrofitting an average-sized coal-fired power plant to combat these emissions concerns and reach compliance with the Clean Air Act is approximately $450 million. Per the National Academy of Sciences, the true cost of coal, when the detrimental health effects of its pollutants are also monetized, adds 12-cents per kilowatt-hour of electricity generated, leading most operators to conclude that plant closure is the only viable option.

Particularly discouraging is that instead of reducing the severe tolls of coal usage though policies that mandate production efficiency while alternative energy mechanisms are brought online, our 1950’s-era coal-fired centralized generation plants continue to dump over 55-percent of the energy they produce back into our air and water, then transmit over long distances the energy that is captured, resulting in another 10-percent loss that adds between 10 and 20-percent to the price of our electricity. Consider a recent study completed by the Massachusetts Institute of Technology forecasting that by 2030, US energy demand is forecasted to be 25-percent greater than in 2010, necessitating $10 trillion in new capital expenditures and increasing CO2 emissions by 30-percent under our current, outdated energy production methods and policies. Add to this equation that centralized generation is prone to blackouts and service interruptions (e.g., the Blackout of 2003 that shut down 265 power plants and disrupted 45-million people in the northeast United States), as well as potentially crippling terrorist attacks, and we are clearly facing an emergency that must be confronted immediately.

Fortunately, there exists a unique opportunity to utilize our waste streams to safely and efficiently generate as much as 17-percent of the United States’ yearly energy consumption. According to Waste Business Journal, approximately 70-percent of the garbage that ends up in landfills each year is comprised of materials that can easily be diverted and repurposed to generate electricity. Solid Waste and Recycling Magazine estimates that there are over 15 billion tons of scrap tires in stockpiles that can be converted into energy components. And the US Department of the Interior believes that over 4 billion tons of forestry waste lies uncollected (e.g., 2 million acres of pine-beetle kill in Wyoming and Colorado alone) and 1 billion tons of animal waste is contained in crude storage facilities, ready to be transformed into power. In the United States alone, these and other waste streams could produce approximately 500 million megawatts of electricity, almost 1 billion barrels of liquid fuels or at least 20 billion tons of solid carbon-based fuels each year. This feedstock, as well as the billions of tons of it currently buried in landfills, represents an enormous domestic renewable resource that is grossly underutilized.

Shortcomings of Current Competitive Approaches

According to the US Department of Energy, there are currently 102 waste-to-energy plants operating in 31 states managing about 11-percent of the solid waste in the United States or about 100,000 tons per day. The $11 billion waste-to-energy industry serves the trash disposal needs of 40 million people, generates about 2,750 megawatts of electricity that powers over 2 million homes and employs about 6,500 workers with annual wages in excess of $150 million. However, these figures lag well-behind those of Europe, where, according to the European Confederation of Waste-to-Energy Plants, over 450 facilities convert to energy about 90 million tons of garbage each year. Denmark converts 54-percent of its solid waste to energy, while France and Belgium each convert 32-percent of their solid waste to energy. Japan leads the world with a waste conversion rate of 69-percent.

Unfortunately, unlike in Europe and Asia, virtually all currently operating waste-to-energy facilities in the United States are incinerators. These incinerators are as notoriously costly and inefficient as coal-fired plants. However, while the growth of alternative approaches to covert waste into usable energy components using technologies such as pyrolysis, plasma arc gasification, anaerobic digestion or thermal recycling was projected by Frost and Sullivan to blossom at 100 new facilities by 2012, most solutions are not optimal for implementation due to four primary reasons. First, as remarkable as it may seem, many solution providers are disregarding baseline economics. Their technologies are prohibitively expensive, costing between $3 and $10 million per megawatt generated, and are handicapped by a high total cost of ownership, particularly in the human resources required to operate and maintain the facilities. In addition, huge tipping fees, monetary incentives and tax credits are usually required to offset the inherently-low efficiencies of the technologies as well as their inability to convert waste into a diverse set of marketable products. Some solution providers even require customers to purchase expensive feedstock or utilize energy crops with little regard for probable changes in market sentiments or global conditions that could render long-term operations extremely challenging –witness the ethanol craze of the mid 2000’s when US farmers boosted corn prices over 400-percent under the hopes of striking it rich. Second, most solutions are simply not decentralized and distributed in nature. Large systems processing hundreds or thousands of tons of waste per day require huge space requirements, have continuous materials handing challenges and must confront staggering pollution control obstacles that add exponential cost. In addition, these technologies cannot be located at the source of the garbage, thus waste is still transported over long distances to communities that did not even generate it in the first place. Third, several solutions are not adaptive. They can convert only specific, sorted waste streams into a limited selection of semi-usable products. Most systems also require footprints that render scaling or customization for future waste streams or capacities almost impossible. Finally, few qualify as being truly sustainable. Many solutions consume more power to operate than they can produce, emit more carbon dioxide per unit of electricity generated than coal-fired plants and frequently require the continued use of a landfill for their by-products.

The MICROPOWER TC Solution and its Advantages

Comprised of standard, commercial-off-the-shelf (COTS) components, many of which have been field tested for over 50 years, the MICROPOWER TC Waste Transformation System is a decentralized renewable energy platform that converts waste into gas, liquid and solid-based energy components using a two-stage, moderate-temperature gasification process that beats all EPA, European and California air quality standards. The most common misconception of using this technology for waste-to-energy conversion is the erroneous claim that “gasification is just another name for “incineration.” Gasification is clearly not incineration, as demonstrated by a side-by-side comparison:

Incineration

- High-temperature; waste is con- verted inefficiently into just heat

- Air added to increase volatility and speed of burning

- Essentially a method of disposal

- Runs dirty

- Can only reduce waste to about 30 percent of original volume, requiring use of landfills

- Ash is toxic with dross, clinkers and slag as additional by-products

- Ferrous and glass materials cannot be recycled

- Requires supplementary energy

- Continuous emissions challenges

Gasification

- Moderate temperature; waste is converted into energy-rich fuels

- Oxygen starved to create complex chemical reactions

- 100-percent resource recovery

- Runs clean

- Can reduce waste to about 2-percent of original volume and byproduct can be sold

- Ash is sterile without any dross, clinkers or slag

- All ferrous and glass materials are recycled after processing

- Sustains on self-generated energy

- Actively manages contaminants before they become emissions

The MICROPOWER TC Waste Transformation System is highly automated, powered by its own self-generated renewable energy and available in prefabricated, 50 ton-per-day modules for quick implementation (about 120 days or less), routine maintenance and easy scalability. Each module requires only 10,000 square feet of building space, making it ideal for housing within existing structures with minor modifications. The transformation process itself is unaffected by moisture, dirt, rocks, combustibles, metal or glass; creates no slag, dross or clinkers; and requires no sorting, shredding or preprocessing of waste. Ideal feedstock includes:

- Municipal Solid Waste

- Industrial Waste

- Construction/Demolition Waste

- Medical Waste

- Scrap Tires and Textiles

- Sewage Sludge

- Oil Sludge

- Liquid Waste

- Animal Waste and Litter

- Food and Beverage Processing Residues

- Agricultural Residues

- Yard Waste

- Forestry Waste

- Natural Disaster Waste

Municipal Solid waste feedstock is reduced 98-percent by volume and is transformed into syngas as the primary product as well as sterile bottom-ash as the only by-product. The syngas can be used to heat a boiler that produces heat or steam; create steam that powers a turbine to generate electricity; directly feed a power generator; or produce other gases, liquid fuels or chemicals through catalytic conversion processes such as Fischer-Tropsch. High-value, carbon-based solid fuels such as charcoal, bio-coal or bio-coke can also be generated by the System when using appropriate feedstock with high fixed-carbon content (i.e., scrap tires, wood waste or forestry residues) at a conversion rate of about 60-percent of original volume with little effect on net syngas output. These energy components can be used in the same manner as those of their coal-based counterparts to reduce GHG emissions with no loss of quality markers such as hardness, ash content or BTU-value. After the waste transformation process, all ferrous materials are recycled while any residual glass is simply mixed with the non-toxic bottom ash and is used as filler for concrete and asphalt or even as an effective strata material for landfills. MICROPOWER offers the only solution in the marketplace that can produce fuel in all three classic states of matter and, as such, the revenue streams of the System could include:

- Sale of electricity

- Sale of charcoal, bio-coal or bio-coke

- Sale of liquid fuel

- Sale of process heat or steam

- Waste tipping fees

- Renewable Energy Certificates (REC)

- Carbon Offsets

- Investment Tax Credits (ITC)

How the MICROPOWER TC Waste Transformation System Works

The MICROPOWER TC waste transformation process starts with untreated municipal, industrial, forestry, agricultural or medical waste being bulk-loaded into the waste processing modules through a hydraulically-operated door at the top of the module. This typically occurs twice per day, as a full processing cycle lasts 10-hours from loading to cool-down. Each module holds roughly 25-tons of waste (50-TPD) without the requirement to prepare feedstock for processing. Materials can be loose, bagged, baled or palletized. The System can also accept a wide range of bulky items such as scrap tires, mattresses, furniture and construction debris. In addition, the process is unaffected by high moisture levels, dirt, rocks, combustibles, metal or glass. For appropriate waste streams, i.e., shredded scrap tires, hardwood biomass, or nut shells, the MICROPOWER solution offers an optional solid-fuel processing module (SFPM) that produces about 25 tons of high-quality, carbon-based, energy components such as charcoal, bio-coal or bio-coke every day from a 50-TPD module.

Once loading is complete, the processing modules are sealed and the waste is never moved or agitated so that small particulates such as fly-ash, heavy metals, NOx and other pollutants are dramatically reduced. The gasification process occurs at the relatively moderate temperatures of 600-800°C in the absence of oxygen and is initiated by a series of inline air heaters within the processing modules. Once the gasification process has commenced –usually in 8 to 10 minutes- the heaters are turned off and an endothermic reaction transitions to an exothermic reaction controlled entirely by the inlet of air into the processing modules. Accurate temperature, air and pressure control as well as safety and environmental monitoring is achieved through an automated control system that allows the process to be slow and stable, thus avoiding any fluctuations that can result in incomplete processing and volatile emissions. Municipal and industrial waste is reduced by 98-percent, leaving only a residue of sanitized, non-toxic ash that is a about 2-percent by volume or 5-percent by weight with no slag, dross or clinkers. Scrap tires and other bio-mass waste is reduced 50% - 60% by volume. After cool-down, hydraulically-operated doors located on the side of each processing module open, allowing ash to be removed with an industrial vacuum. Any residual metals are now sanitized and can be recycled. Any pieces of glass are crushed and combined with the ash to be sold as an additive for concrete or as an amendment for asphalt. If utilizing appropriate waste streams the solid fuel product is vacuumed from the processing module for packaging.

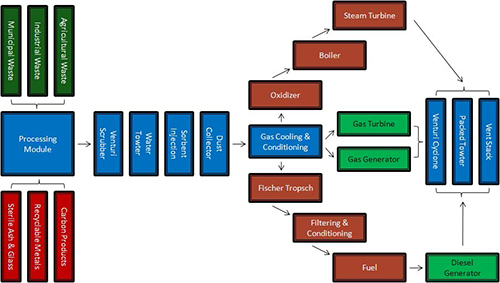

Responding to diverse customer requirements, the MICROPOWER TC Waste Transformation System offers 3 main options for the treatment or utilization of the syngas created during the process (figure 1). The first option is for the syngas to enter into a secondary combustion chamber where it is actively mixed with infused oxygen and heated to 1000-1200°C. Turbulent mixing and multi-second retention of the syngas in the chamber ensures that the combustion process is fully completed. The residual heat of combustion is utilized to create high-pressure steam that drives a turbine. This turbine generates electrical power that can be utilized locally or exported to the grid for distribution. Alternatively, many industries, including paper mills, food and beverage manufacturers, hospitals, universities, textile companies and industrial laundries consume large quantities of steam and thus may be interested in purchasing steam or collaborating in a co-generation project. The steam can also be used to generate large volumes of hot water for heating buildings. Under this option, flue gases are treated with water towers, venture cyclones and dry scrubbers to neutralize dioxins, furans heavy metals as well as NOx, SOx, and VOx. A packed tower treats sulfur and acids as well as removes any trace residual fly ash, with any remaining hydrocarbons oxidized through a flue stack.

The second option is to bypass the secondary combustion chamber and instead utilize the syngas with a low-BTU generator or syngas turbine to create electricity. This option requires the syngas to first pass through a series of water towers, venturi cyclones and dry scrubbers to reduce particles, condensables and tars. Then, any remaining dust or fine ash is removed through a packed tower before oxygen is introduced into the gas stream. Finally, conditioning, heating and pressurization is initiated per the specification of the generator to both optimize the production of power and extend the life of the equipment. Any remaining hydrocarbons are oxidized through a flue stack.

The third option is to bypass the secondary combustion chamber and convert the syngas into liquid condensate fuels. This option also begins with the syngas passing through a series of water towers, Venturi cyclones and dry scrubbers to reduce particles, condensables and tars. Remaining dust or fine ash is removed through a packed tower before oxygen is introduced into the gas stream. At this point, using the Fischer Tropsch process, iron, nickel and cobalt serve as catalysts to reform the syngas into fuel while any remaining hydrocarbons are thermally oxidized through a flue stack. (Note that this last option is not available as part of the base system cost).

Figure 1. MICROPOWER Waste Transformation Process

Competitive Advantage of the Waste Transformation System